Globe Valves

An important use of GLOBE VALVE is to regulate or throttle fluid flow none to full capacity. They may be operated efficiently with the stem in any position from wide open to fully closed. The changed in direction of fluid flow through the valve produces increased resistance & considerable pressure drop in globe valves.

SERVICE RECOMMENDATIONS

• Flow regulation or throttling

• Frequent operation

• Increased flow resistance

• Positive shut-off when closed

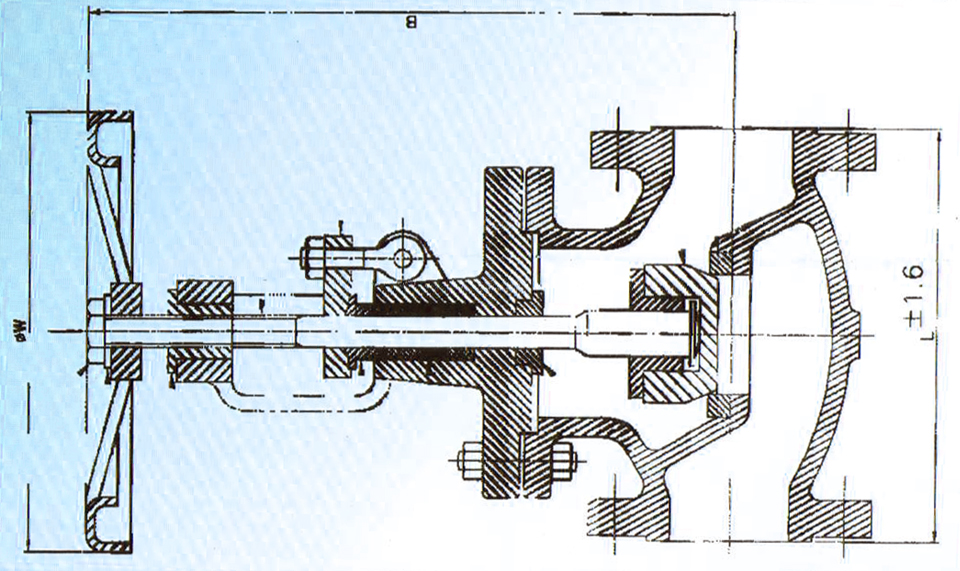

CAST STEEL GLOBE VALVE OUTSIDE SCREW & YOKE TYPE, BOILED BONNET RISING STEM

DISCS/PLUG

Discs & seats in GLOBE VALVE can be repaired or replaced without removing the valve body from the line. The selection of the most suitable discs/seats design is the key to good performance in throttling service FOLLOWING types of Discs are available in “SCENT” GLOBE valves

• Teflon of composition discs

• Fullway or spherical type disc

• Plug type disc

• Needle type disc

Dimention & Details

| PART TIME | MATERIAL SPECIFICATION | ||

|---|---|---|---|

| Body | ASTM A 216 GR. WCB | ASTM 351 GR CF8/CF8M | |

| Bonnet | ASTM A 216 GR. WCB | ASTM 351 GR CF8/CF8M | |

| Disc | AISI 410 | ASTM 351 GR CF8/CF8M | |

| Seat Ring | AISI 410 | Integral With Body | |

| Black Seat | AISI 410 | AISI 304/316 | |

| Stem | AISI 410 | AISI 304/316 | |

| Gland | AISI 410 | AISI 304/316 | |

| Gland Flange | Carbon steel | AISI 304/316 | |

| Gland Packing | Metallic Reinforced Grafted Asbestos | Metallic Reinforced Granted Asbestos | |

| Gasket | Spiral Wound Metallic Gasket | Spiral Wound Metallic Gasket | |

| Yoke Sleeve | All. Bronze | AISI 304/31 8 | |

| Yoke Nut | Cast Iron | Cast Iron | |

| Hand Wheel

Bolts/. Nuts |

ASTMA 193 GR, B7/

ASTM A 194 GR. 2H |

ASTMA 193GR B7/

ASTMA 194 GR.2h |

|

| I-BOLT | ASTM A 193 GR. B7 | ASTM A 193 GR.B7 | |

ALTERNATE MATERIAL OF CONSTRUCTION :-

WC6, WC9, LCB, LC6 CF3, CF3M, CN7M, CG3M, HESTALLOY C & B, MONEL, TITANIUM

CLASS 150

| SIZE | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 |

| A | 108 | 118 | 127 | 165 | 203 | 216 | 241 | 292 | 406 | 495 | 622 | 698 |

| B | 200 | 210 | 245 | 356 | 356 | 381 | 407 | 457 | 610 | 660 | 737 | 838 |

| OW | 100 | 100 | 125 | 140 | 160 | 180 | 200 | 250 | 350 | 450 | 500 | 550 |

All the dimensions are in M.M. Dimensions of Higher sizes & Class will be furnished on request.

CLASS 300

| SIZE | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 |

| A | 152 | 178 | 203 | 229 | 267 | 292 | 318 | 356 | 445 | 559 | 622 | 711 |

| B | 215 | 230 | 265 | 280 | 432 | 483 | 508 | 559 | 710 | 755 | 850 | 975 |

| OW | 100 | 100 | 125 | 140 | 160 | 180 | 200 | 250 | 350 | 450 | 500 | 550 |

All the dimensions are in M.M.

SPECIFICATIONS

| Design Standard | : BS 1873 |

| Face to Face | : ASME B 16.10 |

| Ends :Flanged Ends | : ASME B 16.5 R/F |

| Buttweld Ends | : ASME B 16.5 |

| Testing | : API 598 / BS 6755-1 |

| MANUFACTURING RANGE | ||

|---|---|---|

| SIZE | PRESSURE RATING | |

| 5 MM TO 400 MM | 150 # TO 1500 # | |

| INSPECTION & TESTING | |||

|---|---|---|---|

| CLASS | SHELL | SEAT | |

| HYDROSTATIC | HYDROSTATIC | AIR | |

| 150 # | 30 Kg/Cm2 | 22 Kg/Cm2 | 7 Kg/Cm2 |

| 300 # | 77 kg/Cm2 | 55 kg/Cm2 | 7 Kg/Cm2 |

Available on Request

• Stellite facing

• Jacketed Construction

• Sluice Gate Valve

• Valve Under “X-Ray” Quality

• Gear operated

• Motor Operated Valve